Welding techniques for diamond cutting heads

Diamond cutting heads are important tools used for cutting and grinding materials, and their performance often depends on the strong bond between diamond particles and the cutting head substrate. And this kind of combination often requires welding to achieve. This article will provide a detailed introduction to the welding techniques of diamond cutting heads, including the required materials, steps, and precautions.

Required materials:

Before welding diamond cutting heads, the following materials and tools need to be prepared:

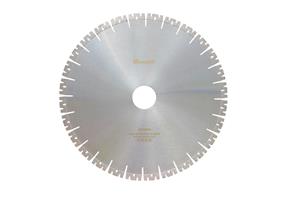

Diamond cutting head: This is a cutting head that needs to be welded to ensure its surface is clean and free of impurities or old welding residues.

Blade base: usually made of metal, used to support diamond particles. Its quality and stability are crucial for welding quality.

Welding materials: Metal with good conductivity and thermal conductivity, such as gold, silver, copper, etc., are usually used as welding materials.

Fixture: used to fix the diamond cutting head and cutting head substrate at the welding position, ensuring stability during welding.

Welding equipment: including arc welding machines, high-frequency induction welding machines, or other suitable welding equipment, used to provide necessary thermal energy for welding.

Coolant: Used to cool the welding area and prevent damage to diamond particles caused by overheating.

Welding steps:

The following are the welding steps for diamond cutting heads:

Preparation work: Firstly, ensure that the work area is clean and free of flammable substances or other hazardous materials. Wear the necessary personal protective equipment, such as goggles and gloves.

Prepare the cutting head and substrate: Clean the surface of the diamond cutting head and substrate to ensure that there is no dust, grease, or impurities. If there are old welding residues, they should be cleaned thoroughly.

Fixture fixation: Use fixtures to precisely fix the diamond cutting head and cutting head substrate at the position that needs to be welded. Ensure alignment and stability between them.

Set welding parameters: Based on the materials of the diamond cutting head and the cutting head substrate, set the parameters of the welding equipment, including current, voltage, and welding time. The correct setting of these parameters is crucial for the success of welding.

Welding process: Start the welding equipment, introduce the welding material into the welding area, generate enough heat to melt the welding material. Ensure that the welding time is not too long to avoid overheating the diamond particles.

Cooling treatment: After welding is completed, quickly place the cutting head into the cooling liquid to ensure that the diamond particles are well cooled and avoid excessive heat treatment.

Inspection and testing: After cooling, carefully inspect the welding area to ensure that the bond between the diamond particles and the tool base is firm, without obvious cracks or looseness. Some tests can also be conducted, such as impact testing, to verify the welding quality.

Cleaning and maintenance: Clean the welding area, remove welding residues and coolant. For the parts that were not successfully welded, repair or re welding is required.

matters needing attention:

During the welding process, avoid excessive heating to prevent damage to the diamond particles.

Regularly inspect welding equipment to ensure its normal operation and prevent unexpected malfunctions.

Ensure the use of appropriate coolant during the welding process to prevent overheating.

Maintain good ventilation in the work area during the welding process to eliminate harmful gases and smoke.