Shaking occurs during the diamond wire saw cutting process

There may be multiple reasons for the shaking of diamond wire saws during the cutting process, which may be caused individually or in combination. Here are some common reasons and solutions:

Uneven cutting material: If the density or hardness of the cutting material is uneven, the diamond wire saw may shake when passing through different material areas. The solution is to ensure the uniformity of the material and, where possible, select appropriate cutting parameters.

Insufficient tension of the rope saw: If the tension of the rope saw is insufficient, it may loosen and cause shaking. Check and adjust the tension of the rope saw appropriately to ensure that it remains within the correct tension range.

Damaged or aged rope saw: The rope saw may lose stability due to damage or aging, resulting in shaking. Regularly check the condition of the rope saw and replace damaged ones in a timely manner.

Cutting speed too fast: High speed cutting may cause the diamond wire saw to jump on the material, resulting in shaking. Reduce cutting speed to make it easier to control.

Inconsistent cutting depth: If the cutting depth is not consistent in different parts, the cutting head may experience different resistance, resulting in shaking. Ensure consistent cutting depth and adjust as needed.

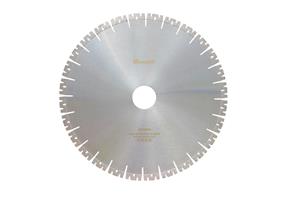

Loose blade: If the blade is not properly secured or loose, it may shake during cutting. Check and ensure that the blade is securely installed.

Workbench instability: The instability of the workbench may also cause shaking during the cutting process. To ensure a stable workbench, consider using more stable work support.

Improper cutting angle: The cutting angle may affect the stability of the cutting. Ensure that the cutting tool is adjusted correctly to the desired cutting angle.

Improper selection of blade: Sometimes, choosing an inappropriate blade may cause shaking. Ensure that the selected blade is suitable for the required cutting task.

Lack of operational experience: The experience and skills of operators are also crucial for avoiding shaking. Training and improving the skill level of operators can reduce the occurrence of shaking.

Wear and aging of the rope saw: Long term use may cause the rope saw to wear out, thereby affecting the stability of cutting. Regularly check the wear level of the rope saw and replace the aging rope saw.

To solve the jitter problem, it is necessary to comprehensively consider the above factors and take appropriate measures according to the specific situation. Usually, regular inspection and maintenance of cutting equipment, proper selection of cutting heads and cutting parameters, and training of operators are effective methods to reduce shaking problems.