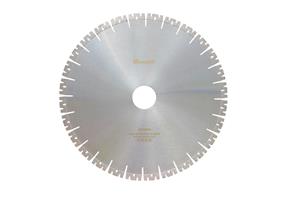

Diamond blade polishing

1、 The benefits of diamond blade polishing

Improving surface smoothness: The surface smoothness of polished diamond cutting heads is significantly improved, which can reduce frictional resistance during cutting and improve cutting efficiency.

Increase durability: Polishing can remove small cracks, impurities, etc. on the surface of diamond cutting heads, improve their durability, and extend their service life.

Improve heat dissipation performance: The polished surface of the diamond cutting head is smoother, which can better dissipate heat, improve heat dissipation performance, and prevent damage to the cutting head caused by heat concentration.

Improve the contact area between the cutting head and the coolant: Polishing can increase the contact area between the diamond cutting head and the coolant, thereby enhancing the cooling effect and preventing the cutting head from overheating.

2、 How to Polish Diamond Cutting Heads

Choose the appropriate polishing agent: Based on the material and polishing requirements of the diamond blade, choose the appropriate polishing agent, such as diamond grinding fluid, polishing paste, etc.

Prepare polishing tools: Choose appropriate polishing wheels, polishing machines, and other tools to ensure that the tool speed and polishing agent supply are appropriate.

Rough polishing: Place the diamond blade on the polishing wheel, apply an appropriate amount of polishing agent, and perform preliminary polishing treatment to remove surface burrs, oxide layers, etc.

Fine polishing: On the basis of rough polishing, finer polishing agents are selected for fine polishing treatment to achieve higher surface smoothness.

Cleaning and drying: After polishing, clean the diamond blade with a cleaning agent and then dry it with a clean cloth.

3、 Precautions to be taken during the polishing process

Control polishing pressure: During the polishing process, it is necessary to control the polishing pressure well to avoid damage to the surface of the diamond cutting head caused by excessive pressure.

Keep the polishing wheel clean: Regularly check the cleanliness of the polishing wheel during the polishing process to avoid affecting the polishing effect.

Control polishing time: During the polishing process, it is important to control the time to avoid excessive wear on the surface of the diamond cutting head due to prolonged exposure.

Avoid high temperatures: During the polishing process, high temperatures should be avoided to prevent thermal damage to the diamond cutting head.

Use safety equipment: Safety equipment such as protective goggles, gloves, etc. should be used during the polishing process to prevent injury.

Attention to storage: After polishing, the diamond blade should be properly stored to avoid contamination and damage.

In short, polishing diamond cutting heads can improve their surface smoothness, durability, heat dissipation performance, etc. However, when polishing, attention should be paid to controlling parameters such as pressure and time to ensure that the diamond cutting heads are not damaged.